What stops Legionnaires Disease? Water treatment chemicals or drift eliminators?

The answer is both.

Did you know that a drift eliminator test certificate will not stop drift or Legionnaires Disease? The actual drift eliminators do!

Have you had your cooling tower drift eliminators physically inspected by a cooling tower expert to ensure that they are working correctly?

Is your water distribution system delivering the water and chemicals correctly?

Did you know that water treatment chemicals will not stop Legionnaires Disease if the water distribution system is faulty?

Did you know that faulty water distribution systems cause faults with the drift eliminators?

Can’t remember the last time your drift eliminators and water distribution system were properly inspected by a cooling tower expert?

We sat down with one of the owners of FlowMatrix an Australian-owned and operated company, servicing Melbourne, Victoria, Geelong, Ballarat, Wodonga, Albury, Sydney, Canberra, Wollongong, Newcastle, Orange, and Tamworth, among many others. Renowned for their expertise and unwavering commitment to ensuring peak performance. Darren Driscoll is a cooling tower specialist, who has 33 years of industry experience. Darren has extensive knowledge of all things drift eliminators and water distribution systems.

In this blog, Darren has shared how drift eliminators and water distribution systems play crucial roles in the efficient and effective operation of cooling towers—a vital component in industrial processes and HVAC systems. These components are designed to manage water within the cooling tower, ensuring optimal heat dissipation while minimizing water loss and environmental impact. Most importantly, how regular inspections and maintenance of drift eliminators and water distribution systems are essential for not only the long severity of the cooling tower but for the safety of your facility and even the lives of people.

Water Distribution and Drift Eliminators’ Role in Cooling Towers

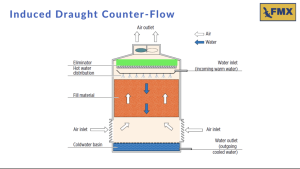

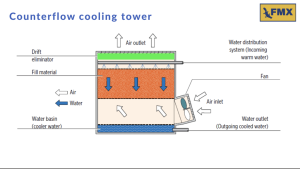

Water distribution and drift eliminators are crucial components in a cooling tower, a device used to remove waste heat from a process and transfer it to the atmosphere. Cooling towers are commonly used in industrial facilities, power plants, and HVAC air-conditioning systems.

Water Distribution

The primary function of water distribution in a cooling tower is to evenly distribute water over the fill media which is a heat exchanger. Fill media increases the surface area for air and water contact, facilitating heat exchange and cooling of the process water. Proper water distribution ensures efficient heat transfer by preventing dry spots in the fill media. Uneven water distribution can lead to reduced cooling efficiency and increased energy consumption. Faults are often blocked nozzles or holes, poor water flow, blocked pipes, broken pipes, blown seals and joints, missing nozzles.

Components of a Water Distribution System

- Nozzles: Devices that spray water over the fill media. They can be of various types, such as spray nozzles, rotary nozzles, or gravity distributors.

- Distribution Basins: Structures that collect and evenly distribute water to the nozzle’s, ensuring water is evenly spread over the fill media.

Drift Eliminators

Drift eliminators not only hold back water, but chemicals and bacteria. They play a crucial role in maintaining water efficiency by reducing water loss from the cooling tower. They also help in meeting environmental regulations by minimizing the release of water droplets into the surrounding area. By effectively capturing and preventing the release of water droplets into the environment, drift eliminators reduce the potential for Legionella, chlorine, and other harmful chemicals exposure to people in the vicinity of the cooling tower.

Below is an article from the Sydney Morning Herald about faulty drift eliminators that caused a legionella outbreak in a local facility in Sydney:

https://www.smh.com.au/national/nsw/concerns-about-cbd-legionnaires-risk-raised-after-last-outbreak-20240104-p5ev9a.html

These chemicals can not only be harmful to people, but if your drift eliminators are faulty, they can splash over rooftops, causing scale, corrosion of steel structures and roofs, staining windows, and even damaging nearby cars.

Components of a Drift Eliminator

- Honeycomb or Blades : Drift eliminators typically consist of a series of sheets or blades that create tortuous paths for the air to pass through, causing droplets of water, chemicals and bacteria to be separated and collected back into the cooling tower.

- Material: Drift eliminators are often made from materials resistant to corrosion and decay, such as PVC (polyvinyl chloride) or other plastics.

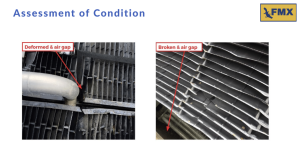

Proper maintenance and regular inspection of water distribution systems and drift eliminators are essential to ensure the efficient and safe operation of cooling towers. Over time, scaling, fouling, damage, and even breaking to these components can occur, impacting not only the performance of the cooling tower but also causing a massive safety issue. Regular inspections from professionals like FlowMatrix are necessary to maintain the cooling tower’s effectiveness, longevity, and overall safety.

Regular inspections (recommended at least once a year) from professionals like FlowMatrix are necessary to maintain the cooling tower’s effectiveness, longevity, and overall safety.

Get a FlowMatrix Inspection

FlowMatrix’s highly trained specialists are experts at carrying out mechanical inspections, repairs, and interpreting risk management planning audits to ensure the smooth operation of drift eliminators and water distribution for all brands of cooling towers. Darren mentioned that during their inspections, they normally discover many missing parts, brittle blades, air gaps, dirt, scale, blockages, and broken parts.

It is essential to ensure your drift eliminators and water distribution systems are not only installed properly but are also maintained to safety expectations. FlowMatrix recommends a yearly inspection to ensure drift eliminators are not damaged, not scaled, not brittle, have no air gaps, and the air seals are fitted correctly!

When FlowMatrix conducts their inspections, they are looking out for many things, one of those being cleanliness. If FlowMatrix notices your cooling tower has poor hygiene, they will recommend a Superclean or Deep clean, which has the best hygiene procedures. This is not just clean your cooling tower but it also provides thorough reports that include photos, sketches, maintenance plans, and even further recommendations to get your issues addressed so your cooling tower is up to scratch.

Many companies do NOT have the correct skills and experience to perform tasks like FlowMatrix, who have extensive knowledge in everything cooling towers, from taking on repairs to offering simple advice on parts.

Darren mentioned that in most Australian states, there is NO regulation stating that drift eliminators need to be inspected, so it does not get done unless a Legionnaires Disease outbreak occurs. Bit late for anyone who contracts Legionnaires Disease!

In fact, many cooling tower owners think that having a certificate stating that drift eliminators have been installed is all they need for a safe cooling tower, which couldn’t be further from the truth. Cooling tower drift eliminator certificates do not stop drift loss — not the required 0.002% maximum drift loss as specified by the certificate:

- Hundreds of litres of water loss into the air each hour.

- Litres of hazardous chemicals are discharged into the air and environment each hour.

- Potentially millions of bacteria are discharged into the air each hour.

Darren shared an example, “Imagine getting your brakes installed in your new car, then never taking it to get a service just because you have a certificate that says ‘I have brakes installed in my car,’ even if it was 20+ years ago.” FlowMatrix can avoid all of these problems by offering modern solutions that will do the job and do it well.

FlowMatrix’s goal is to provide modern-day cooling tower solutions for their clients that address the six core principles of a quality cooling tower job:

- – The design

- – The scope of work and outcome must address performance optimization

- – Water savings

- – Energy savings

- – Government Compliance

- – Reduce Legionella risk

- – Prevent environmental damage

FlowMatrix Uses High-Quality Parts (Brentwood)

The cheap drift eliminator that many large companies around Australia use and install to keep the price down, can cause systems to clog up, shut down, and fail after only 2-3 years.

FlowMatrix puts their trust in Brentwood as they believe in the integrity of the manufacturer Brentwood Industries, which has produced high-quality products for OEM and installers for 50+ years. The blocks and sheet materials are made to a high standard, have the correct fire rating, are traceable to recognized international standards and Australian standards such as AS / NZS 3666, have supporting information with product datasheets, and have been designed with engineering expertise. Brentwood PVC materials are engineered to be strong, lightweight, UV-stabilized, modular, and fire-resistant.

These factors will contribute to a longer life of around 10-20 years for your cooling tower. It seems to be a simple choice if you want your fill pack and drift eliminators to last for many years instead of a couple of years for which the cheap copy lasts.

Flowmatrix’s unwaveringly committed to delivering top-quality services and products. They adhere to industry-standard best practices and leverage cutting-edge technology for diagnosing, repairing, and replacing drift eliminators and water distribution systems.

Call FlowMatrix today to get a cooling tower inspection or for whatever cooling tower problem you may have.

The guys really know their stuff and love helping people.