These systems are used for coating the interior of mild steel, stainless steel, and fiberglass cooling towers. Structural steel supports. Steel ductwork and fan discharges. The amazing thing about this system is the two-hour curing time between coats which is a great time saver for our clients. Submerged applications

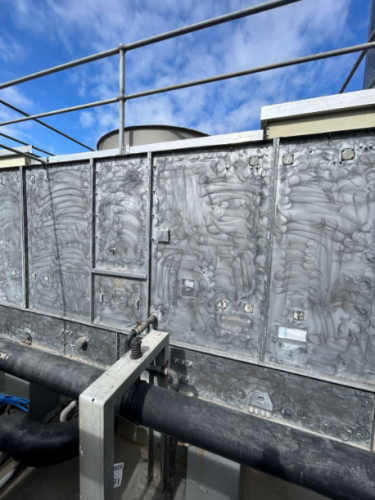

RepelCoat RCR-300 is a three-stage coating system that is applied on top of the initial preparation process to the failing steel and leaking seams / joints. The preparation involves blasting the steel surface back to bare metal, repairing holes, and removing failed sealant on the steel surface.

- The first coat is a primer coat that locks onto the steel.

- The second coat is the flexible surface that moves with the cooling tower vibration and people walking on the surface.

- The third coat is our chemical resistant coating that can withstand all the terrible conditions that a cooling tower can attack.

- This is a bonded system that is flexible and extremely tough. If a tradesperson cuts it with a grinder or drills it, the damage is localized. This stops the

RepelCoat system lifting off the base metal. It will corrode locally in the damaged area, but this is easily repaired by a touch up coat to the affected area.

Application by FlowMatrix – Cooling towers are an extreme environment for the interior tower steel surfaces. The water is chemically treated with highly corrosive chlorine to control bacteria growth. The pH range can cause the water to be corrosive if it gets too high or too low. The water is generally at a temperature range from 15 deg C and can be as high as 40 to 60 deg C in some cases. Hot water and chemicals cause the sealants in the seams or joints to fail causing water leaks. There is also excessive vibration that is caused by the rotating fan and the pump that pushes water into and out of the cooling tower. The extreme vibration opens the seams by loosening the bolts, so the sealant slides out of the joints. Water leaks also occur due to steel corrosion that cause holes in the interior steel surfaces such as the water basin, the casing, the fan wheel cowls, the fan ducting, and the fan snouts.

Once corrosion takes hold your steel cooling tower is on the way to failure unless the RepelCoat coating system is applied to save it. Coating the cooling tower interior surfaces while the corrosion or water leaks are just starting to take hold is the best action as this is a cost-effective process, being approximately 25% of the cost to replace a cooling tower. To replace a cooling tower, you need to disconnect all the plumbing connections, disconnect the ducting, remove the failed corroded or leaking unit, rework the supports, install the new unit and re-plumb the cooling towers. That is very expensive, and chances are if you install a new steel cooling tower you will need to coat it or replace it in five to ten years’ time.

RepelCoat is a registered trademark of FlowMatrix in Australia.

Formed in 2018 RepelCoat coating products are designed to provide specialized coating systems for cooling tower installations, cooling tower repairs, water leak sealing, pipework, steel supports, plant room floors, roof surfaces under cooling towers, pipework penetrations through floors and roofs, Cool store panel sealing and grouting systems for concrete plinths, or hollow core filling.

The challenge with cooling tower related coating requirements is that the product selected must be able to withstand, chemical attack, high or low pH levels, corrosion, erosion from fast moving water and grit, vibration, excessive movement, foot traffic, and a variation of materials such as steel / copper / fiberglass / plastic.

RepelCoat Rapid RCR-200 / 300 / 400. These systems are used for coating the interior of mild steel, stainless steel, and fiberglass cooling towers. Structural steel supports. Steel ductwork and fan discharges. The amazing thing about this system is the two-hour curing time between coats which is a great time saver for our clients. Submerged applications

RepelCoat PV-300 / 400. These systems are used on pipework, vessels, tanks that are associated with cooling towers or refrigeration systems. Non-Submerged

RepelCoat PUME-200 Membrane coating system for concrete, steel and cool store panels.

RepelCoat Grout GSW-200 for sealing / repairing hollow cores in steel fiberglass or concrete.

RepelCoat MP-100 Submerged concrete resurfacing repair.

For the application of the RepelCoat systems our personnel are trained in using the correct PPE, ventilation procedures, the application of the products, and hazard control.