Did you know that anybody working on Cooling Towers must have a range of skillsets, experience, qualifications, be compliant with various state and regulatory authorities around Legionaries disease, and be trained and compliant with industry safety standards and procedures?

Yes, that’s a lot to take in right there, but this is exactly what is needed before any work on a cooling tower can take place.

A lot of cooling towers can be an extremely unsafe environment for anyone who needs to work on them. Cooling Towers have critical parts that need a routine inspection, cleaning, and repair, so maintenance and repair people are exposed to unacceptable safety hazards that MUST be managed and controlled. Some of these safety hazards include working in confined or restricted spaces, slips and trips, exposure to electricity, falls from heights, exposure to hazardous chemicals, and even dangerous bacteria that grows inside cooling towers.

Latest news from our NSW FMX team

Skills to work on any cooling tower – NSW Regulations 1st March 2023 Regarding the NSW government introducing regulations to hold a Mechanical and Medical Gas certificate and license to carry out Installation – Repairs – Maintenance – Water treatment of cooling towers.

FLOWMATRIX has 30+ years of cooling tower knowledge and experience, with qualified technicians and team leaders who have specialized skillsets and on-site training on the job. This is what they are bringing to the cooling tower industry!!

There is no one certificate, course, or trade qualification to remotely have anyone carry out cooling tower work correctly and safely. Cooling towers should never be overlooked as their efficient operation is crucial if you want to eliminate safety risks for your employees, customers, the general public, and your business.

A rundown of FlowMatrix’s skills and six quality targets!

The team at FlowMatrix are highly trained specialists and experts at carrying out mechanical maintenance and repairs, component repairs, and interpreting risk management planning audits to ensure the smooth operation of all brands of Cooling Towers.

It is essential to ensure your cooling tower is not only being installed properly but is also safely maintained.

Based on our research, there are not many companies that have the correct skills and experience to be performing these needed tasks. FlowMatrix on the other hand, have extensive knowledge in everything cooling towers from taking on repairs for any type of Cooling Tower, to offering simple advice on parts.

Jason Christensen, a director at FlowMatrix has extensive knowledge of all things cooling towers a few years at Coolclean as a cooling tower technician, ten years as a cooling tower industrial water treatment a technician with Solenis, three years doing specialized coating applications with Select Coatings and is now on his fifth year with FlowMatrix as a General Manager and director in 2022.

Darren Driscoll, a Director at FlowMatrix, has extensive knowledge of all things cooling towers, indeed Darren comes from a background of actually designing and manufacturing all types of Cooling Towers in Australia, how is that is for the experience!

Landon Morley, NSW project manager, has a growing knowledge of all things cooling towers after doing four years with HydroChem as a water treatment technician, and now on his fifth year with FlowMatrix doing cooling tower projects, installations, spare parts and sales.

Jason Christensen – General Manager, VIC

Landon Morley – Project Manager, NSW

Darren shared an analogy saying, “Imagine having a 20-year-old car that needs the brakes replaced, and your mechanic is recommending putting brakes on the car that were made 20 years ago, for that car back THEN. Those brakes are most likely full of asbestos, will not last long and probably won’t even do the job properly while also being a health risk to everybody”. Original Equipment Manufacturer (OEM) can be a very poor choice for new cooling tower parts, especially when there are superior and modern parts available today.

FlowMatrix can avoid all these problems by offering modern solutions that will do the job and do it well by providing modern-day cooling tower solutions for their clients that address the six core principles of a quality cooling tower job.

FlowMatrix Quality Targets

1. Bacteria Control / Risk Control

2. Government Compliance

3. Performance Maximization

4. Water Savings

5. Energy Savings

6. Environmental Protection

Must haves to work on any cooling tower in Australia!

1: Cooling Tower Insurance:

FlowMatrix has insurance that is valid for any cooling tower job.

To install, repair, maintain and clean cooling towers, you must have comprehensive 20k public liability insurance that does NOT exclude Legionella disease.

Legionella is a reportable disease and all parties that work on cooling towers require insurance.

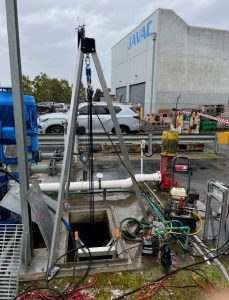

2: Confined space/restricted access:

Before FlowMatrix starts any work on a Cooling Tower they ask the question, does it involve entry into a confined space or restricted access? Does a confined space risk assessment need to be conducted by a competent person, who must also complete a confined space entry permit?

Now you might be wondering does everyone need Confined Space Entry training and permits. In most cases YES if you need to enter any cooling tower. If the space is not deemed Confined, you MUST consider it a restricted access that requires a person to enter and another to standby as a safety watch / spotter. Employers are

required by law to provide employees with training, an entry permit, a standby person, and a rescue plan written by a competent person before they enter a confined space. Restricted access does not require a permit, but you must ensure that there is a safety watch / spotter to assist someone hurt in a restricted access cooling tower and call for help

FlowMatrix is a government-compliant company with the authority to write and provide permits for any job they undertake.

3. Working at heights:

Incredibly important to have certification to work at heights, on platforms, ladders, and equipment, to control risks and implement safe access such as:

- Portable ladders

- Scaffolds

- EWP (scissor and boom lifts)

4. First aid training:

● Level 2 first aide training or above is critical to enter or supervise any cooling

tower confined or restricted access space

5. Chemical handling/safety training:

Training is super important to make sure everyone involved do not get injured

Eliminate Possible chemical hazards:

● PPE: Safety gear including full body chemical proof clothing, rubber boots, eye

protection, ear protection, rubber gloves, and gas and mist P2 mask to provide

protection to your airway

● Training: Ensure workers are trained to safely work inside a cooling tower

space, around it, near motors and fans, being splashed with water containing

chemicals, dirt and mould that contains bacteria such as Legionella.

● Provide personal protective equipment that is suitable for the nature of the work

and the hazard, and that is used or worn by workers who have been trained in

its use and care.

Trained to isolate cooling tower chemical dosing equipment for safe entry

Working inside the cooling tower

Safety Procedures for Repairing, Installing, and Maintaining a Cooling Tower:

Repairing, installing, and maintaining a cooling tower comes with some very important steps that can’t be overlooked. The risk and the safety of the service provider, any company employees, and even rescue workers or health workers that may need to attend and assist in emergencies.

Example in SA South Australia

https://www.safework.sa.gov.au/workplaces/work-sites-and-facilities/cooling-towers

Skills that FlowMatrix specialists must have:

Darren spoke about the process of selecting their team members, as there is no actual higher schooling, or post-education or degree available solely for Cooling Towers. FlowMatrix handpicks their recruits that come from other related industries such as plumbers, engineers, mechanics, chemists, mechanical designers, cleaners, carpenters, painters, fibreglass, electricians and labourers

These recruits are then put through FlowMatrix’ s intense training that comes with a range of on-site and off-site activities they complete, gaining invaluable on-the-job knowledge and to handle all aspects of Cooling Towers installations, repairs and maintenance.

Some of these skills include the following:

- Equipment Maintenance

- Repairing

- Operation Monitoring

- Operation and Control

- Internal Plumbing

- Water testing

- Specialized costings

- Drift eliminator knowledge

- Working at heights

- Mechanical design drafting and structural design

- Rescue plans

- Pressure power washing

- Equipment Selection

- Complex Problem Solving

Comprehensive inspection and reports:

Darren discussed FlowMatrix’ s process of coming out to your cooling tower to access and diagnose it first before anything else is done. This extremely detailed cooling tower analysis can include sketches and photos. FlowMatrix take pride in their work which is why they like to personalize each inspection to ensure your cooling tower is truly up to standard, ensure that you meet all government regulatory standards, and that your risk management plan is complete and accurate.

Once a cooling tower system is registered, a risk management plan must be completed and inspected annually (every 12 months) in Victoria and every 5 years in NSW.

FlowMatrix specializes in producing high-quality, long-lasting results, which is critical if you want to achieve the most efficient cooling results, correct heat rejection, save money and time, keep food production lines cool, chiller chilling, and process cooling lines in factories running properly.

What this can include:

● Whether or not the part you’re looking for will work.

● What is the most suitable replacement part for a specific type of cooling

tower?

● How to recommend a high-performance component or parts such as drift or

mist eliminators, air intake splash louvers, fill pack

● It's important to know what the Australian or government standards are, and that the parts are always certified, approved, and current. AS/NZS 3666 is an Australian recognized cooling tower standard.

● The most effective options and solutions

FlowMatrix supplies and installs Safe access platforms and ladders to get to all the

critical components and the fan drives

● Encourage people to consider modular parts and components, such as drift

eliminators for fill packs and splash louvres for air intakes.

● It is important that mechanical components such as motors, fans, shafts, bearings, pulleys, belts, gearboxes, and taper locks are in good working order and do not fail while in service. FlowMatrix has the experience and engineering data to understand the best cooling tower choices that save companies time and money.

Do you want a performance analysis done on your cooling tower to recommend the highest-performance new parts? Not a problem as FlowMatrix will provide data, output, kw rating, and drift loss data.

An Audit Report:

An individual risk management plan and custom-designed solutions to your problem. In each report, FMX includes a detailed sketched-out diagram with photos that were taken on-site.

Recommendations/ actions:

They then get back to you promptly with a very personalized quote explaining what needs to be done and why it needs to be done, you can then confirm what FlowMatrix has diagnosed for your cooling tower then they will come back and provide you with exactly that. A quote with a scope of work, parts required, recommendations, compliance information, and photos that show faulty components.

Be safe when it comes to your cooling tower, let the professionals handle all your needs, allowing you to always have peace of mind for yourself, your employees, and your business.

Call FlowMatrix to come out and have a look at your cooling tower today.