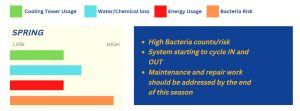

It is now Spring, and we are quickly approaching the heat of summer.

Spring brings us increased detections of the Legionella bacteria as the cooling towers start to cycle in and out. The same occurs in Autumn for the same reason.

Summer, as the heat intensifies, there is an inordinate demand on the cooling tower and the associated cooling systems. So, if your cooling tower and associated equipment are not in good physical condition you may face bigger problems leading to major downtime waiting for parts and labour to rectify unforeseen faults.

Therefore, ensuring that the cooling tower mechanical drives such as fans, bearing, motors, pumps are ready to go and go hard for 5 months is critical. Just as critical is to ensure that the internal components such as drift eliminators, fill pack, splash louvers and the water distribution systems are safe, compliant, and in functional state to also go hard for the next 5 months.

Have you looked at the service reports, repair quotations, risk management plans and audits to determine if there is outstanding work from last summer?

It is easy to forget such issues when the demand for the cooling tower has been low over the winter period.

Get ready – Plan – Prevent is the best action for cooling towers before Spring and Summer!!

Performance and risk

Some of the things you need to address for your cooling tower during warmer days are:

- The water level controller is functioning properly which is very crucial to your operation. Validating that it is both controlling the water set point properly

- Zero water and chemical leaks – Water and chemicals splashing out, leaking onto the ground, excessive drift from the fan drives. Loosing chemicals is a water treatment risk to control bacteria and an EPA / environmental issue, both land and air.

- Unusual noises coming from the cooling tower is a sign that something might be wrong. Pumps, fans, shafts, motors, water surging

- Unusual water flow through the fill pack, channelling, overflowing via fans or drains.

- It is critical to ensure all interior components are not damaged, are working correctly, and are in the correct position, such as drift eliminators, water distribution pipes, fill pack, air seals, and nozzles not blocked.

When to Plan Cooling Tower Maintenance and Repairs

Planning for spring and summer will ensure the overall performance, health and safety, durability, efficiency, and compliance of your cooling towers and the associated systems.

These are some of services that FlowMatrix offer that may be helpful. Please reach out to FlowMatrix team if you need any further assistance!

Mechanical drive repairs & replacement

https://flowmatrix.com.au/mechanical-drive-replacements-and-repairs/

Repair, Rebuild and Servicing

https://flowmatrix.com.au/repair-rebuild-and-servicing/

Cooling tower parts

https://flowmatrix.com.au/parts/

Corrosion and Water leak repairs