Are you looking to replace your air intake louvres? Not sure what you’re looking for or just looking for alternative supplier options? We sat with one of the owners of FlowMatrix, and a cooling tower specialist Jason Christensen, who has industry experience of 20 years and now with FlowMatrix as a General Manager and Director. Jason has extensive knowledge of all things air intake louvres.

Air intake louvres might seem like small components within the vast landscape of cooling tower infrastructure, but their impact on cooling towers’ efficiency and performance is undeniable. These unassuming elements play a significant role in balancing airflow, protecting against external elements, minimizing water loss, reduces Legionella risks and enhancing energy efficiency.

In the blog Jason will be sharing with us how Flowmatrix’s innovative louvre designs continue to contribute to the evolution of cooling tower systems, making them more effective, sustainable, and adaptable to the needs of industry!

FlowMatrix technicians installing retrofit air intake louvres.

The Role of Air Intake Louvres in a Cooling Tower:

Air intake louvres are essential components of cooling towers. These louvre systems are designed to regulate the flow of ambient air into the tower. They serve a multitude of crucial roles that contribute significantly to the overall cooling efficiency of the tower:

- Sunlight Mitigation: Exposure of sunlight inside the cooling tower basin can affect the water treatment chemical levels and lead to the growth of algae and other microorganisms, causing fouling and reducing heat exchange efficiency. Air intake louvres help to block the sunlight, minimizing the impact on wetted surfaces and hence, prevents unwanted biological growth, and reduces the risk of Legionella.

- Minimizing Water and Chemical Loss: Efficiently designed air intake louvres can help reduce the amount of water loss due to evaporation and splash out. By controlling the evaporation and splash out, the tower’s operational water loss can be minimized, leading to improved water conservation, and reduced operational costs.

- Chemicals Inside Cooling Tower: Sunlight exposure to the wetted surfaces can affect the water treatment chemical inside the cooling tower and can accelerate the deterioration of equipment, affecting its lifespan and performance. Air intake louvres blocks the sunlight exposure and as such the integrity and durability of surrounding equipment are preserved.

- Preventing Debris Entry: Louvres act as a barrier against debris, leaves, birds, and other airborne contaminants. Preventing these materials from entering the tower helps maintain the cleanliness of the tower’s internal components and preserves its efficiency.

- Preventing bacteria and legionella: Air intake louvres serve as crucial components in preventing the growth and dissemination of harmful bacteria, including Legionella, in cooling towers.

A display of FlowMatrix Air Intake Louvres

Common Issues with Air Intake Louvres

Air intake louvres are subjected to harsh environmental conditions, including temperature fluctuations, UV, chemical and airborne contaminants. As a result, their material can deteriorate over time, compromising their functionality and overall cooling tower performance.

Here is a list of air intake louvre issues FlowMatrix regularly come face to face with that mean it is time for a replacement:

- Reduced Cooling Efficiency: One of the primary indicators that your air intake louvres require replacement is a noticeable decline in cooling efficiency. If the louvres are not functioning optimally, they may reduce airflow and heat exchange. This can result in higher operating temperatures, decreased system efficiency, and potentially even equipment failure.

- Physical Damage: Regular inspections of the air intake louvres are essential. Look out for signs of physical damage such as cracks, chips, warping, blocked drainage holes, broken or corroded frames. These issues can compromise the structural integrity of the louvres, rendering them less effective.

- Clogging and Contaminant Buildup: Airborne debris, dust, and contaminants can accumulate on the louvres over time, obstructing airflow, and impeding heat exchange. Excessive clogging can lead to increased maintenance demands and decreased cooling tower performance. If routine cleaning fails to rectify the problem, replacement may be the best solution.

Jason considers it crucial to mention that many of the jobs that they are called out for revolve around splash louvres. These splash louvres are seen in Crossflow towers utilizing horizontal slats to keep cooling water in within the cooling towers. Unfortunately, this design presents several drawbacks, including Sunlight Mitigation, Water Loss, Chemical Loss, Airborne Contaminants, Maintenance Challenges and Reduced Heat Exchange Efficiency. Also, allows birds to enter and bathe inside the cooling tower basin.

FlowMatrix’s designed Air Intake Louvres

Our specialised technicians assembling the stainless-steel frames on the air intake louvres for installation.

Stainless Steel Framed PVC Air Intake Louvres:

The FlowMatrix PVC cellular stainless steel framed air intake louvres have superior design features to other louvres in the market for many reasons such as:

- The design of the anti-water and anti-chemical splash out has been improved by angling the plastic profile sideways and upward. This not only prevents splashing but also blocks out sunlight to reduce bacteria growth.

- To ensure durability, strong stainless-steel frames have been used to resist breakage caused by dropping. Unlike PVC frames that crack and break easily, these stainless-steel frames can withstand impact and can be reused even if the PVC air intake louvre material is damaged due to knocks, hail, or physical contact.

- This innovation results in significant cost savings as there is no need to purchase a new frame when the PVC deteriorates over time. Flowmatrix’s stainless steel frames have a lifespan of up to four times longer than those of other companies’ air intake louvres, making them a reusable product for many years to come!

Recent Job Installing Stainless Steel Framed PVC Air Intake Louvres

Below is a job FlowMatrix have recently completed where they installed stainless steel framed PVC air intake louvres to a cooling tower.

The installation was for various Evapco cooling towers in a management facility located in Melbourne CBD.

Evapco tower with old parts before installation of the new air intake louvres

New FlowMatrix SS louvres installation on the Evapco cooling tower.

Inside view of the cooling tower with new install

Retrofit Air Intake Louvre Panels:

FlowMatrix technician installing retrofit panel louvres for a crossflow cooling tower.

FlowMatrix’s retrofit air intake louvre panels are supported by a non-corrosive fibreglass FRP frame. Resulting in louvres that are lightweight, corrosion-resistant, and capable of withstanding harsh environmental conditions.

Here are some of the best features in FlowMatrix’s retrofit air intake louvre panel design:

- Enhanced design to prevent water splash-out.

- Blockage of sunlight to minimize bacteria growth in cooling tower basin water, including Legionella.

- Interlocking profile for secure installation.

- Excellent airflow with minimal pressure drop.

- UV stabilized for a durable black finish that maximizes light absorption.

- Made from PVC plastic that is resistant to chemicals.

Recent Job Installing Retrofit Air Intake Louvres

Below is a job FlowMatrix have recently completed where they installed retrofit air intake louvre panels to a cooling tower for hospitals.

Hospitals are subject to strict regulations and guidelines concerning air quality and infection control. Regular maintenance and replacement of air intake louvres align with these regulations, helping facilities meet the required standards and maintain a safe environment for the patients and staff.

Before installation

During installation

After installation

FlowMatrix technician installing retrofit louvres in a crossflow cooling tower in a food manufacturing facility.

Types of Cooling Towers FlowMatrix Supply/Install Air intake Louvres for:

FlowMatrix supplies stainless steel FRP and FRP Panel louvres for all cooling tower brands, makes and models including:

- Aquacool

- BAC

- Budge Ellis

- Coolboy

- Coolmaster

- Davenport

- Evapco

- F Muller

- Fibreflow

- Fibre Tech

- Gatorade

- Hamon

- Hydrothermal

- Lakeside

- Linear

- Marley

- Maxichill

- Messan

- Muller

- Radic

- Shinwa

Other Places to Install Air Intake Louvres

FlowMatrix is one of the few companies that can provide the “supply, sell, and deliver” of air intake louvres for absolutely every type of cooling tower in Australia. They also provide a very rare after-sales service care to their clients, where Jason or another team member from FlowMatrix regularly provides a service of instructions at a distance, over a phone call or even a Facetime call.

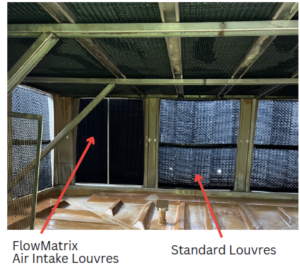

This air intake louvre installation on the outside of a building was a case where FlowMatrix sent out their air intake louvres for the business to install themselves, providing helpful tips over the phone for a proper installation:

Before installation

During and after installation of the retrofit panel louvres

Air Intake Louvres fitted in between panels

This FlowMatrix client was experiencing issues with rainwater entering their building. To address this problem, FlowMatrix suggested implementing their honeycomb louvre design, which effectively prevented rainwater from infiltrating the building through the fresh air intake louvre panels.

Additionally, this solution offered several other benefits, such as blocking out sunlight to reduce the growth of mould and bacteria in the building and preventing small vermin like birds from entering through the Louvre panels. Moreover, the installation offered a low-pressure drop.

Jason mentioned, “It is actually very common to find air intake louvres in various other locations beyond cooling towers as they can provide many benefits in other places, including commercial buildings, HVAC facilities, and even storage spaces for poultry, onions, and potatoes.”

Why Choose Flowmatrix’s Air Intake Louvre Designs

FlowMatrix, as the leader in cooling tower solutions, offers a range of innovative air intake louvres designed to meet the complex demands of industrial and commercial processes. Flowmatrix’s air intake louvres are engineered with cutting-edge design principles to ensure efficient airflow, heat exchange, and environmental control within cooling towers. Their louvres are meticulously crafted to address challenges such as debris prevention, water and chemical losses, and regulatory compliance.

Air Intake Louvre SS 2021

Application: Cooling towers, air intake ducts, storage sheds.

Capability: Stop water and chemical splash-out, stop direct sunlight, allows full air flow, stops vermin entry,

Restricts rubbish and debris entry.

Compliant:

AS/NZS3666 part 1, 2 and 3 Compliance for cooling tower applications.

Here are some other reasons why FlowMatrix’s air intake louvres are the best choice:

- The drainage holes have been precision-cut using laser technology to ensure optimal drainage.

- The handles have been designed for easy removal, cleaning and reducing the risk of accidentally dropping them.

- The frames of the louvres are made of stainless steel, providing durability and long-term cost savings.

- Blocks out sunlight, effectively preventing bacteria growth in the cooling tower basin water, including legionella.

- The black finish enhances light absorption.

- The louvres are made from PVC plastic that is resistant to chemicals.

- The improved design of the louvres prevents water splash-out, reducing the loss of water and chemicals into the environment.

- The interlocking profile of the louvres prevents gaps from forming between the segments.

- The louvres ensure excellent airflow with minimal pressure drop, maintaining optimal cooling performance.

- The PVC material used in the louvres is UV stabilized, ensuring a long service life even in direct sunlight. Additionally, the materials used are rigid and non-corrosive.

Retrofit panel louvres in a round counterflow cooling tower.

FlowMatrix Quality Targets

- Bacteria Control / Risk Control

2. Government Compliance

3. Performance Maximization

4. Water and Chemical Savings

5. Energy Savings

6. Environmental Protection

Get the right advice when it comes to air intake louvres, and let the professionals handle all your needs, allowing you to always have peace of mind for yourself, your employees, and your business.

Call Jason or the guys at FlowMatrix to come out and have a look at your air intake louvres today.