FlowMatrix continually strives to innovate and provide top-tier services that meet the evolving needs of their clients. In line with this commitment, they are excited to introduce their latest offering: Engineering Performance Clean. This new service is designed to revolutionise the way cooling tower maintenance is approached, ensuring that clients receive the most comprehensive and advanced care for their cooling systems.

About Darren, the Owner of FlowMatrix

Darren, the visionary owner of FlowMatrix, has been a driving force in the cooling tower industry for years. His journey began with a passion for mechanical systems and a desire to improve the standards of maintenance in the industry. Darren’s profound commitment to excellence and innovation has consistently pushed the boundaries to ensure that FlowMatrix remains at the forefront of cooling tower maintenance and technology.

Under Darren’s leadership for the last 33 years, FlowMatrix has grown from a small operation into a reputable name in the industry. His dedication to quality and customer satisfaction has been the cornerstone of this growth. Darren’s expertise in engineering and his relentless pursuit of innovation have been instrumental in the development of the Engineering Performance Clean service. This service reflects his dedication to providing clients with cutting-edge solutions that meet their specific needs. His vision has always been to offer services that not only meet but exceed industry standards, ensuring the highest levels of performance and reliability for cooling towers.

What is Engineering Performance Cleaning?

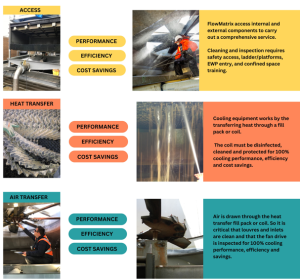

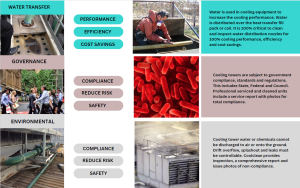

Engineering Performance Clean is a comprehensive and specialised service designed to assess and maintain cooling towers from an engineering perspective. Unlike traditional maintenance services that focus on routine cleaning, this service offers a full-scale evaluation aimed at ensuring the optimal performance and longevity of cooling towers. This approach is rooted in a deep understanding of engineering principles and a commitment to applying the latest technological advancements in the field.

Comprehensive Assessment

The Engineering Performance Clean service includes a range of detailed assessment activities, each designed to provide a thorough understanding of the current state of a cooling tower. These activities include:

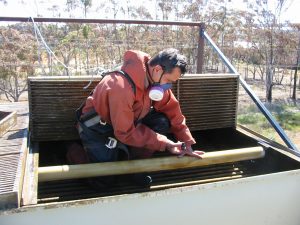

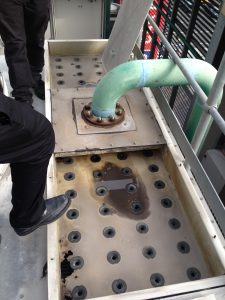

- Detailed Inspection: The FlowMatrix team conducts a thorough examination of all components of the cooling tower. This inspection is meticulous and aims to identify any potential issues or areas of concern that could affect the performance and efficiency of the cooling tower. They look at everything from structural components to operational systems to ensure nothing is overlooked.

- Photographic Documentation: To ensure complete transparency and provide a clear visual record, FlowMatrix takes high-quality photos throughout the assessment process. These photos document the condition of various components of the cooling tower, highlighting any issues or areas that require attention. This visual documentation is an invaluable tool for understanding the current state of the cooling tower and for planning future maintenance activities.

- Comprehensive Report: At the conclusion of the assessment, FlowMatrix provides a detailed report summarizing their findings. This report is comprehensive and includes:

- Comments: Expert insights and observations on the current state of the cooling tower. The FlowMatrix team provides detailed notes on any issues identified during the inspection, along with their potential impact on the performance and efficiency of the cooling tower.

- Recommendations: Based on their findings, FlowMatrix offers actionable advice on necessary repairs, upgrades, or maintenance tasks. These recommendations are designed to address any issues identified during the inspection and to enhance the performance and longevity of the cooling tower.

- Quotations: To ensure complete transparency and facilitate budget planning, FlowMatrix provides cost estimates for any recommended work. These quotations are detailed and cover all aspects of the recommended repairs or upgrades, helping clients make informed decisions about their maintenance activities.

Key Components of Engineering Performance Cleans

During an Engineering Performance Clean, FlowMatrix focuses on the following key components of a cooling tower to ensure optimal performance and longevity:

Spray Systems

- Nozzles: Checked for blockages to ensure proper water distribution.

- Correct Nozzle Fitting: Verification that the correct nozzles are fitted for the system’s needs.

- Pipes: Inspected for blockages or leaks to maintain efficient water flow.

2. Fill Pack

- Condition Check: The fill pack is inspected to ensure it is not broken, smashed, or brittle, which could affect cooling efficiency.

3. Header Boxes

- Blockage Inspection: Ensures that header boxes are free of blockages, allowing proper water distribution throughout the cooling tower.

4. Drift Eliminators

- Material Integrity: Drift eliminators are checked to ensure they are not brittle, scaled, or failing.

- Air Gaps and Issues: Inspection for any air gaps or other issues that could lead to inefficient operation.

- Suitability: Recommendations are made if a different type of drift eliminator would be more efficient in reducing water and chemical loss.

5. Fan Drives

- Efficiency Check: Ensures that the fan drives are working efficiently and not causing other issues with the cooling tower.

6. Ball Float Valve Set Points

- Overflow Prevention: Inspection to ensure the Ball Float Valve set points are correctly adjusted to prevent overflow and unnecessary water waste.

Before- Water overflowing After- New Valve installed

7. Air Intake Louvers

- Sunlight Blockage: Inspected to ensure they are effective at blocking sunlight, which helps reduce biological growth inside the cooling tower.

8. Overall Structural Integrity

- Structural Components: General inspection of the cooling tower’s structural elements to ensure there are no signs of wear or damage that could affect the tower’s performance.

9. Compliance Clean

- Safety Cleaning: A basic clean is performed to ensure safety during the engineering inspection and to meet compliance requirements.

10. Documentation and Reporting

- Photographic Documentation: High-quality photos are taken throughout the inspection to document the condition of each component.

- Comprehensive Reporting: Detailed reports are provided, including observations, recommendations, and quotations for any necessary repairs or upgrades.

These components are thoroughly examined and assessed to ensure that the cooling tower operates at peak efficiency, reducing the risk of breakdowns and extending the system’s lifespan.

The Engineering Perspective: More Than Just Cleaning

The FlowMatrix Engineering Performance Clean is not just about cleaning; it’s about ensuring that every component of the cooling tower is functioning optimally. The cleaning aspect of the service, which comprises only 5-10% of the overall service, is critical but secondary to the comprehensive engineering evaluation. This evaluation covers everything from ensuring nozzles are not blocked to checking fill packs for brittleness and verifying that drift eliminators are in good condition and appropriate for the unit.

This service is designed to address the technical aspects of cooling tower maintenance, which are often overlooked. The aim is to prevent small issues from escalating into major problems, which could lead to costly repairs and downtime. By focusing on the engineering components, FlowMatrix ensures that cooling towers operate more efficiently, use less energy, and contribute to overall water and chemical savings.

Long-Term Value and Cost Efficiency

One of the unique aspects of the Engineering Performance Clean service is its long-term value. Unlike routine cleaning services, which need to be performed every three to six months, this service is recommended every one to two years. While the service is more expensive than routine cleaning, it offers significantly more value by ensuring that the cooling tower operates at peak efficiency. This efficiency can result in cost savings through reduced energy usage and less frequent repairs.

Furthermore, this service can be amortized across the standard routine maintenance schedule. For example, if a routine clean costs $500 and is done four times a year, the addition of an Engineering Performance Clean at $2,000 every one or two years can be averaged out, making it a cost-effective solution for long-term maintenance.

Why Choose FlowMatrix?

FlowMatrix has a proven track record of excellence in the cooling tower industry. Their commitment to quality and customer satisfaction has earned them a reputation as a trusted partner for cooling tower maintenance. Here are a few reasons why clients should choose FlowMatrix for their cooling tower maintenance needs:

- Experience and Expertise: With years of experience in the industry, the FlowMatrix team brings a wealth of knowledge and expertise to every project. Their engineers are highly skilled and have a deep understanding of cooling tower systems and the latest advancements in maintenance technology.

- Customer-Centric Approach: At FlowMatrix, customers are at the center of everything they do. They take the time to understand specific needs and tailor their services to meet those needs. Their goal is to provide the highest levels of service and support, ensuring complete satisfaction.

- Innovative Solutions: FlowMatrix is committed to staying at the forefront of the industry by continually innovating and improving their services. Their Engineering Performance Clean service is a testament to this commitment, offering a cutting-edge solution that sets a new standard for cooling tower maintenance.

- Transparency and Integrity: FlowMatrix believes in complete transparency in all their dealings. From detailed reports and photographic documentation to clear and accurate quotations, they ensure that clients have all the information they need to make informed decisions about their maintenance activities.

- Proven Results: Clients have seen significant improvements in the performance and longevity of their cooling towers as a result of the FlowMatrix services. Their track record of success speaks for itself, with numerous satisfied clients who trust them with their cooling tower maintenance needs.

FlowMatrix Quality Targets

FlowMatrix is committed to achieving specific quality targets that ensure the highest standards of cooling tower maintenance. These targets include:

- Bacteria Control / Risk Control: Ensuring that cooling towers are free from harmful bacteria and that all potential risks are managed effectively.

- Government Compliance: Meeting all regulatory requirements and industry standards to ensure compliance with government regulations.

- Performance Maximization: Enhancing the operational efficiency of cooling towers to achieve maximum performance.

- Water and Chemical Savings: Implementing strategies to reduce water and chemical usage, promoting sustainable practices.

- Energy Savings: Optimizing cooling tower operations to reduce energy consumption and lower operational costs.

- Environmental Protection: Adopting environmentally friendly practices to minimize the impact of cooling tower operations on the environment.

For more information about the FlowMatrix Engineering Performance Clean service or to schedule an assessment, contact them today. Let FlowMatrix help maintain the peak performance of your cooling towers. They are here to provide the expertise and support needed to ensure that cooling towers operate at their best, delivering reliable and efficient performance for years to come.

FlowMatrix is dedicated to helping clients achieve the highest levels of performance and reliability for their cooling towers. Their Engineering Performance Clean service is just one example of how they are continually innovating and improving their services to meet the evolving needs of their clients. Contact FlowMatrix today to learn more about how they can help achieve maintenance goals and ensure the long-term success of cooling tower systems.

View one of our Engineering Performance Clean Report below: