Over the years, Flowmatix has had the pleasure of completing many cooling tower jobs for a diverse range of clients. From installing brand new towers to repairing and maintaining existing ones, they have worked on projects of all sizes and complexities all over Australia in places like Sydney, Wollongong, Newcastle, Ingleburn, Liverpool, Wetherill Park, Penrith, Bega, Bathurst, Canberra, Fyshwick, Belconnen, Queanbeyan, Geelong, Melbourne CBD, Frankston, Laverton North, Dandenong, Portland, Ballarat, Shepperton and Wodonga!

Flowmatrix takes great pride in showcasing the exceptional cooling tower jobs they have successfully completed over the years. With years of expertise and a passion for excellence, we sat down with a cooling tower expert and one of FlowMatrix’s owners, Jason Christensen who has over 18 years of experience in the Cooling tower industry. Jason’s extensive knowledge of all things cooling towers, comes from a background of plumbing, water treatment, coatings, and repairs of many cooling towers in New South Wales, ACT and Victoria, now how is that for the experience?

By sharing a few of Flowmatixs most successful jobs over the years, we hope to provide value to their clients and help them better understand the importance of proper cooling tower maintenance and upkeep. Whether you are a plant manager, an engineer, or a facility manager, we believe you will find Flowmatrix insights and expertise useful in ensuring that your cooling tower works effectively.

So, let’s dive into a few of the most successful cooling tower jobs and explore how Flowmatrix have helped its clients achieve their goals.

1.

Client: Water Treatment Supplier

Location: Braeside, Victoria

Job Type: Computer System Cooling Tower Upgrade

Jobs FlowMatrix Performed

- They removed the access hatch

- They removed the old fill pack and air intake louvre material

- Installed a new modular block fill pack

- Fitted and installed new air intake splash louvres

- Installed a new ball float valve, arm and ball

- Refiled tower and made sure all the water set point levels were correct

- De-isolate and recommission

- Flowmatrix supplied a new fill pack along with a ball valve and assembly

- Flowmatrix installed new sunblock-out air intake louvres.

- All waste was removed off-site and Flowmatrix disposed of it.

Materials Flowmatrixs used and suppled

- Brentwood counterflow fill pack block 2400 X 10 off

- Sunblock air intake louvres 2400 X 3 off

- Bob – 1/2″ high flow brass turbo valve assembly with stem plastic float, Stainless steel threaded rod & hardware

2.

Client: Paper mill Company

Location: Ingalburn NSW

Job Type: Steel Basin coating system. RepelCoat

Jobs Flowmatrix Performed

- Removed all the access hatches and the front basin panels. (This is to gain access to the basin for Sandblasting.)

- Sandblasting failed to coat the basin

- Removed the used Sand from the basin

- Repaired holes within the basin with a steel flat sheet, also repaired minor holes within fan snouts at the basin end.

- Applied Repelcoat Grey top coat to the prepared basin, and allowed it to dry overnight.

- Applied Marine grade sealant to all joints, bolt heads, screws and repaired areas (Allowed drying time)

- Re-installed the front access panels, used butyl mastic for sealing and new Hex screws

- Removed the old access hatch seals, and prepared the area for new seals

- Applied fixing glue then applied the seals

- Re-installed access hatches, along with new S/S Wing nuts where possible

- Removed the traps from the top of the cooling tower

- Pressure cleaned the cooling tower from top to bottom, removed all rubbish from the site, and pressure cleaned all the area around the cooling tower

- De isolated the system

- Clean up the area and removed all rubbish

- Closed the JSA and other permits

- Completed a full detailed report incorporating photos

Flowmatrix recommendations

- Flowmatix recommends replacing the air intake fan guards and meshes with a simpler mesh and guard all in one. (This will make maintenance and cleaning a lot easier and quicker)

3.

Client: Manufacturer

Location: Riverstone, NSW

Job Type: AirTrunk Project Derrimut

Jobs Flowmatrix Performed

- Flowmatrix carry out a COVID test prior to the job onsite

- Complete JSA and permits

- Install a new spray pump pipework

- Installed a new spray pump pipe work to CT 5

- Cleaned up the area and removed all the rubbish

Materials Flowmatrixs used

- New PVC pipework

- connecting flange

- Consumables

- Primer and glue

4.

Client: HVAC Contractor

Location: North, NSW

Job Type: Install New Brentwood Drift Eliminators

Jobs Flowmatrix Performed

- Complete the permits and JSA

- Lock out / tag out

- Remove the old drift eliminators and dispose of them off-site to landfill

- Supply and install the FRP fibreglass support where required

- Supply and fit the new modular PVC Brentwood counter-flow drift eliminators CF80Max De-isolate

- Closed the permit and JSA.

Flowmatrix Recommendations

- Air intake louvres are scaled and are coming out of the frame, the fill pack is heavily damaged which is reducing the water flow access hatch for drift eliminators is kept close to the metal pole

5.

Client: Water Treatment Facility

Location: Revesy, NSW

Job Type: Cooling tower Repair And Reseal

Jobs Flowmatrix Performed

- Completed the JSA, obtained permits, and locked out the unit

- They removed the air intake louvres and tarped up the cooling tower

- They Removed the access hatch, drift eliminators, and the fill pack blocks

- They Removed the old sealant from the upper legs, basin legs, and basin joints

- Etched all areas to be coated

- Taped up all the seams and joints in preparation for sealing

- Applied the RepelCoat Rapid RCR-200 coating system to the prepared seams, joints of the casing, and basin

- Apply RepelCoat Rapid RCR-200 and weave matt to the cracks in the basin.

- Re-installed the fill pack, the drift eliminators, and the access hatch.

- Re-installed the air intake louvres

- De-isolate the tower and check for correct operation and no leaks

- Closed the permits and the JSA.

Flowmatrix Recommendations

- The drift eliminators have air gaps caused by the PVC pipework. Recommend replacing with new modular drift eliminators with airtight seals.

- The fill pack is brittle and beginning to break upon removal and re-installation; it is recommended to replace it with a new Brentwood CF 1200 fill pack to increase water distribution and therefore increase the efficiency in the cooling tower.

- There is a hairline crack within the centre strip of the basin, Flowmatrix recommended cutting out the foam core and replacing it with RepelCoat Rapid Gravel Mix. To reinforce the centre strip and not allow water to sit underneath the crack.

6.

Client: Water Treatment Facility

Location: Braeside, Victoria

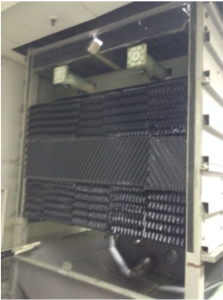

Job Type: Crossflow Cooling Tower Rebuild

Jobs Flowmatrix Performed

- Arrived at the site, completed site permits, and JSA

- Isolated the cooling tower and applied personal locks and tags

- Drained the cooling tower

- Removed the cross braces on both sides of the cooling tower

- Removed all the old fill packs and disposed of them off-site

- Pressure-cleaning the whole cooling tower

- Applied RCR-200 across all of the basins and joints.

- Cut and install the new modular fill pack blocks with an FRP support system

- Cut and installed the FRP air seals for the fill pack.

- Reinstalled the cross braces for the cooling tower

- Installed the FRP framework for the AILs

- Cut and installed the AILs

- Refilled the cooling tower

- Isolated the cooling tower

- Cleaned up all the materials and rubbish from the site

- Closed permits and JSA

Flowmatrix Recommendation

- When the system was isolated, a lot of corrosion was found to settle at the bottom of the basin. This could potentially lead to blockages throughout the pipework.

- The current eliminators are brittle and require replacing

7.

Client: Water Treatment Facility

Location: Sydney University

Job Type: A14 Main Quad – Fill Pack & Air Intake Louvre Replacement

Jobs Flowmatrix Performed

- Lock out or tag out

- Drained the unit

- Remove the old fill pack and supports

- Supply and install the new FRP fill pack supports

- Supply and install the new modular PVC fill pack blocks (fill, air intake louvre, drift eliminator).

Flowmatrix Recommendations

- The fan motor is found to be heavily corroded, Flowmatrx recommend replacing it

8.

Client: HVAC Supplier

Location: Gordon, NSW

Job Type: Installation of access Ladder and Platform to Cooling Tower Fan Drive

Jobs Flowmatrix Performed

- Complete JSA/Permits

- Loaded the site with access to platform materials.

- Build and install the access platforms and ladders

- Close JSAs and permits

Flowmatrix Recommendations

- Flowmatrix recommends replacing the fan motor and hub assembly due to being heavily corroded

9.

Client: Water Treatment Supplier

Location: Sydney University

Job Type: C43F F Block Cumberland- Air Intake Louvre Replacement

Before After

Jobs Flowmatrixs Performed

- Flowmatrix Isolated, locked and tagged out the cooling tower

- Install the new PVC interlocking honeycomb air-intake louvre material to stop sunlight and water splash gaps from forming

- De-isolate and remove the tags

10.

Client: Water Treatment Supplier

Location: Dandenong South, Victoria

Job Type: Cooling Tower Reseal and Rebuild

Jobs Flowmatrix Performed

- Removed the access hatch and removed the fill pack, drift eliminators, and louvre and disposed of them off-site

- Installed new FRP fibreglass fill pack supports

- Power-washed the interior surfaces to remove dirt and bacteria

- Prepared all interior joints and seams for sealing

- Applied the RepelCoat RCR-200 coating system to all the prepared joints and seams

- Removed trash associated with this activity

- Supplied and installed a new modular block fill pack

- Installed FRP back-to-back channel and supplied and installed new modular drift eliminators

- Installed a new stainless steel splash deflectors

- Installed the FRP angle backing supports, and supplied and installed new air intake louvres.

- Installed the FRP angle corner covers

- Reinstalled the access hatch

- Filled the basin and checked for leaks

- Packed away all the tools and equipment used and removed any leftover rubbish of site

11.

Client: Office Space

Location: Haymarket, NSW

Job Type: Cooling Tower Service

Jobs Flowmatrix Performed

- Complete JSA/Permits

- Electrically disconnected the fan motor

- Loaded the site with a new fan motor and rigging equipment

- Set up the gantry, remove the old motor, and discard it offsite

- Installed a new 7.5 kw fan motor to suit the cooling tower operations

- Install new fan blades and hubs to match the current setup

- Electrically connect the fan motor and test the fan

Flowmatrix Recommendations

- Flowmatrix noted the condenser pump isolation switch caught fire once it was turned back on due to something wrong with it. Flowmatrix informed the building management.

- Recommend that the drift eliminators be replaced as they are the old original drift eliminators as these eliminators could not be removed for cleaning or maintenance purposes.

12.

Client: Construction Supply Company

Location: Broadmeadows, Victoria

Job Type: Complete Cooling Tower Rebuild

Jobs Flowmatrix Performed

- Arrived on site, completed the site permits, and JSA

- loaded the site with materials

- Isolated the cooling tower and applied personal locks and tags

- Drain the basin and removed the air intake louvres

- Removed all the fill packs

- Removed all the scale and debris from the basin and pressure-cleaned the cooling tower

- Cut and installed all the FRP supports for fill packs, drift eliminators, and air intake louvres

- Cut and installed the new modular XF75 fill pack blocks to the cooling tower

- Cut and installed the new modular drift eliminators

- Cut and installed the new modular air intake louvres

- Reinstalled the strainer and refilled the cooling tower

- Removed the isolations

- Discarded all rubbish off-site

- Packed up the tools and equipment

- The plant room was swept, and the roof was thoroughly cleaned

- Closed permits and JSA

13.

Client: Mining Company

Location: Melbourne, Victoria

Job Type: Cooling Tower Service

Jobs Flowmatrix Performed

- The cooling tower was cleaned and inspected as required

- The cooling tower was unable to be dosed prior to cleaning due to access hatches that could not be removed while the cooling tower was running

- The basin was filled with a significant amount of mud, which was removed via the sucker truck that was supplied

- The tower was cleaned with a pressure washer on the back of the sucker truck.

- The ball float was replaced with a new float valve and arm.

- Drift eliminators were replaced with new Brentwood drift eliminators

- The fill pack was in reasonable condition and was cleaned from below and above

- The fans were found to be unbalanced due to the buildup of dust, which has turned hard.

- The fan cowlings were found to be leaking heavily as the tower was overflowing

- The connection between the fan cowling and the cooling tower needs to be resealed due to the heavy water loss

Flowmatrix Recommendations

- Flowmatrix recommends resealing with Repelcoat Rapid

- Fan wheels, shafts, bearings, and pulleys are to be replaced

- Reseal the connection between the fan and the fan cowling.

- Recommend a fill pack replacement

- Recommend the replacement of the fan wheels and shaft pulleys

Flowmatrix takes great pride in all their work over the years, which is why they like to personalise each procedure and give recommendations to best benefit their clients. Ensure your cooling tower is being looked after by “THE” cooling tower experts!

Get some expert advice today! Give Darren or the guys at Flowmatrix a call for a free quote!