FlowMatrix has been keeping cooling towers operational and safe for 30+ years

Our policy for all work that we undertake for our customers is to ensure our work addresses all our solution targets.

FlowMatrix solution targets are

- Performance optimisation

- Water saving

- Energy saving

- A modular installation design to allow easy ongoing maintenance

- About safety

- Reducing the biological risk

- Compliant with government regulations

- Protecting the environment

- Providing safe access

- Cost effective

There are many clever ways to repair, rebuild or install a cooling tower

Our solution targets are incorporated when we carry out a site inspection, when we take photos and write a detailed quotation. Quotations include current condition, required action to address issues, a detailed scope of work, individual parts pricing, and the labour required as number of personnel x required hours. This is a fully transparent process, so the client knows exactly what they are getting and what they are paying for and it does not end there.

On completion of the quoted job, we issue a service report that confirms what work was carried out and photographs of the actual work delivered. We only use high quality parts that are chosen as suitable for the application, traceable back to a supplier, that have product data sheets and have technical support. Many cooling tower companies only focus on the cost to supply a new cooling tower, to repair or to rebuild a cooling tower. This is very poor economically. Cooling towers that are installed or repaired with only the cost as the primary consideration are generally not compliant and cost a lot more short and long term, with hidden costs and modifications required to make them safe and compliant.

Cost based installation and repairs faults

- Poor access to maintain the cooling tower in accordance with state government regulations. For example, no safety access platforms, ladders, and walkways. Poor access within the cooling tower configuration to remove all components easily and safely for ongoing maintenance.

- Motors, fans, fill pack, drift eliminators, air intake louvres, water distribution systems: Installation methods of fill pack and drift eliminators that do not allow removal. This occurs in brand new cooling towers as well as poorly designed repairs.

- Excessive water and chemical loss from defective parts in brand new cooling towers as well as poorly designed repairs. Water splash out, drift loss, water leaks from basins, overflow, faulty ball valves. EPA intervention required, due to environmental chemical damage to ground or stormwater, air pollution from chemicals, excessive noise from fans and water splash.

- Work safe intervention due to injury caused by unsafe access, chemical contact to eyes or skin, lifting heavy components, falls from portable ladders, failed fan drives that are poorly maintained.

- Legionnaire disease outbreaks caused by no safe access to clean and service drift eliminators or the water distribution system.

- Excessive water loss from leaks, splash-out and over spray.

- Excessive power usage caused by fouling of fill pack that is not designed to be removed and cleaned to remove sludge and scale. It is law in some Australian states to clean all interior surfaces of a cooling tower so cooling towers that are not designed with modular components are not compliant.

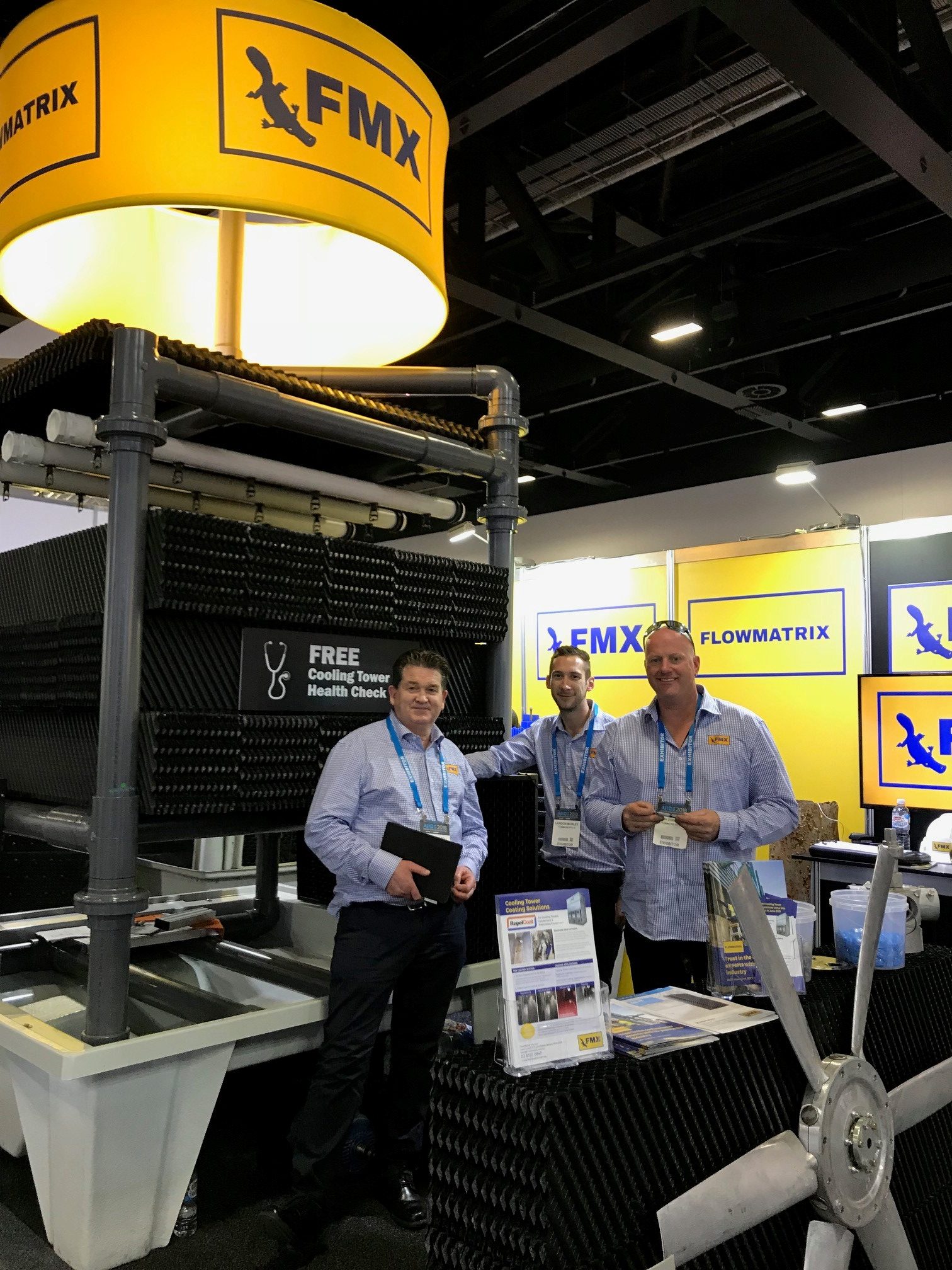

FlowMatrix is 100% Australian owned and operated specialising in commercial and industrial cooling tower site work in Victoria, NSW and ACT. We have also completed projects in Tasmania, Queensland and SA and supplied spare parts to WA and the NT. With over 30 years of experience, we have replaced and repaired many brands and makes of cooling towers, being steel, fibreglass, timber and even concrete.

There are many cooling towers installed that no longer have representation in Australia, but we have documentation on most cooling towers ever installed in Australia so generally, they all can be repaired or sized for replacement.