Great work! We have just had the maintenance contract for the site approved and your work had a lot to do with it.

Keeping cooling towers operational and safe for 30+ years

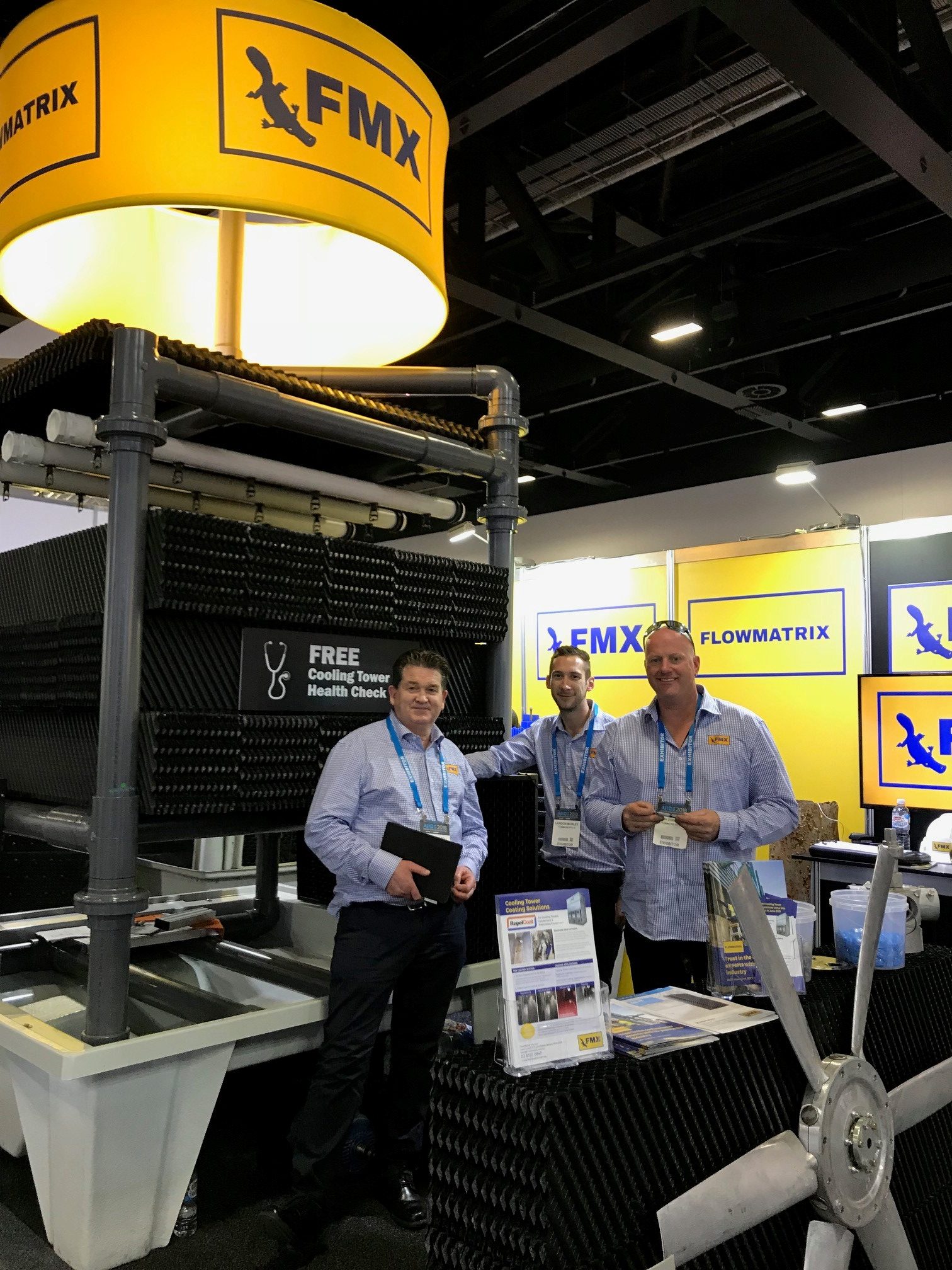

FlowMatrix is a 100% Australian owned and operated company specialising in the inspection, repair, maintenance, and installation of cooling towers for commercial and industrial premises throughout Australia.

FlowMatrix has been keeping cooling towers operational and safe for 30+ years

Our policy for all work that we undertake for our customers is to ensure our work addresses all our solution targets.

FlowMatrix solution targets are:

See what our clients are saying about us..

Find out what FlowMatrix has been up to, and get the inside information on all things Cooling Towers.